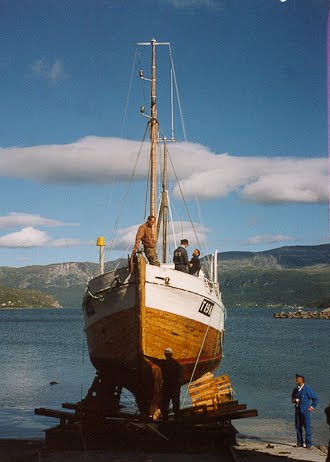

Mer og mer kommer på plass, og det planlegges å sjøsette Brottsjø 19. august i anledning Foldvikmarkedet som arrangeres årlig av Gratangen Kystlag. Vi gleder oss til å vise publikum resultatet.

Mer og mer kommer på plass, og det planlegges å sjøsette Brottsjø 19. august i anledning Foldvikmarkedet som arrangeres årlig av Gratangen Kystlag. Vi gleder oss til å vise publikum resultatet.The launching date is getting closer, and Brottsjø is getting more and more complete. We are planning to launch the boat at 14:00, the19.th of August so that we can show it at the coastal-culture festival in Foldvik that same weekend.

Drivinga fortsetter, og nå er det undervannsskroget som står for tur.

Drivinga fortsetter, og nå er det undervannsskroget som står for tur.The caulking continues, and the hull below the waterline is under work.

Alt av dekk er ferdig drevet og beket.

Alt av dekk er ferdig drevet og beket.The caulking of the deck is finished, and sealed.

En god del halvrundjern er montert, og rør-rekkene er under arbeid.

En god del halvrundjern er montert, og rør-rekkene er under arbeid.Quite a lot of the hardware is mounted, and the railing is being worked at.

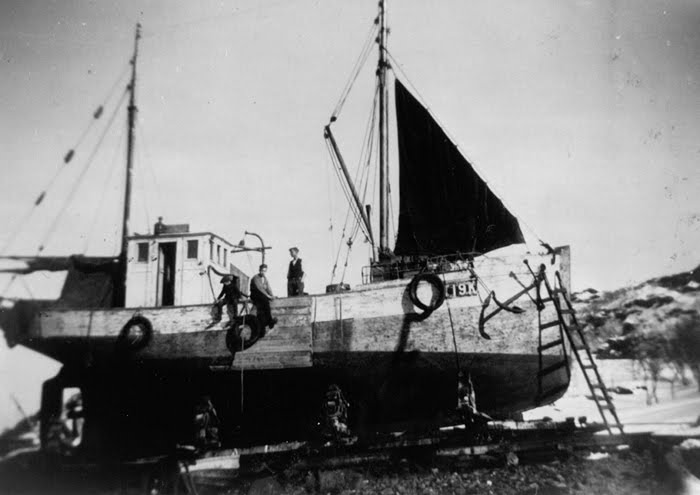

Fiskeriregistreringsmerket er malt på og baugbeslag montert. Kappa er også ferdig.

Fiskeriregistreringsmerket er malt på og baugbeslag montert. Kappa er også ferdig.The registration mark for fishing is back. The companion way/cabin porthole is also finished.

Jay is peeling out old caulking.

Dielseltanks, piping and machiney is refurbished.

The cylinder and other parts of the Finnøy-engine are stripped from old paint, primed and painted with hammered-finish anti-rust paint like it was when Trygve Nilsen had the boat.

Engine parts.

More engine parts. The oiltank for the stove in the cabin is made new, and is to be placed at sb-side of the deck in the front of the boat.

The engine is being rebuilt in the boat after the parts has been refurbished in the workshop. Brottsjø has a controllable pitch propellar which is powered by hydraulics, these have new sealings and the piston and cylinder here has been honed.

Engine parts that were rusty were stripped down and treated with Owatrol penetrating oil. Then primed with Jotun-primer with some Owatrol penetrating oil blended in - this will make the primer stick better to the surface. The top finish is light blue Hammerite hammered finish.

A reinforcement was mounted behind the beam - which made the air tank end up some centimeters behind its origin. This messes up the access to the cranes and handles of the airtank. We have to figure out what to do with this - a possible solution is to extend the cranes and handles.

Parts of Brottsjøs electrical circuitry. Den andre sitter i akterkant av keisingen, og her finner en også knivbryterne for hovedstrøm og gløding.

More parts of the electrical circuitry, the switch-blade switches are the main-switch and the other one for the diesel glow plug. Styrhuset har fått seg en omgang med skraping, pussing, grunning og maling. Styrhuset og keisingen er i aluminium.

The aluminium steering house has also been refurbished. En del spikerslag var dårlige, og måtte skiftes ut. Alt brukbart panel ble pusset og brukt om igjen.

The beams behind the panel was in bad condition, and had to be replaced. The panels was refurbished and used over again. Styrhusvinduene har også fått seg en omgang med pussing og overflatebehandling.

The windows from the steering house also got their share of surface treatment.

1 comment:

I've seen one of the images that might need some Owatrol Paint Conditioner. The invention is very nice and it needs to last long right? So, by now it should be taking cared of with the proper chemical to preserve it.

Post a Comment